How to build SUV Box Robot for LEGO Competitions

There are a few main challenges with box robots and in the following tutorial we would like to resolve them. Read on and let's see how we could do this.

- #971

- 19 Aug 2018

There are a few main challenges with box robots and in the following tutorial we would like to resolve them. Read on and let's see how we could do this.

You need not confine yourself to the use of drawing tools. You can easily choose an image from the internet, print it out, and stick it to the clock surface. Or maybe you have other ideas of how to customise the clock face?

It's a box! It's a robot! It's a box robot. Box robots are very popular on different robotics competitions involving LEGO Mindstorms like the FIRST LEGO League or World Robotics Olympiad. Let's start with a brief introduction and continue in the next videos with explanation on the features of the robot and why such robots are frequently used.

We used dental floss to draw lines from the clock face diagonals, and drilled the holes where those lines met.

You need not place the clock's arrow hole in the center. As this is a design choice, you can be creative and place it wherever you wish. You can even customise the shape of the clock face as well, so it is not a plain square like ours.

This video tutorial is part of the series on how to make your robot 100% precise and accurate. We accomplish the Emergency Walk mission 10 out of 10 times. The attachment works. Every time the attachment is started in successfully accomplishes the mission and this is one of the most difficult missions on FIRST LEGO League competitions ever.

Don’t worry about which electrical contact you connect to the positive or negative output terminals of the speed controller. The cables can always be swapped later.

Here is Lintu. It is a marvelous LEGO Mindstorms EV3 Animal robot that looks like Kiwi, the famous New Zealand bird. It is quite rare to see a Kiwi bird in person. But fear not, we've prepare a robot that looks almost exactly like the original.

Do not solder anything to the speed controller.

Here we start with a second box robot that we would like to build. It is in a way improvement to the first robot and we would take a look at its features.

You need a very short exposed wire to solder to the DIP switch. Try not to strip too much ot it, as it may come in contact with the other end of the switch, effectively bypassing it.

The robot should park in the parking positioned in the north-east corner of the field.

At the end of the match the robot is completely in the parking area in the north-east corner of the field: 50 points.

Be careful not to cut the cable too short, as it is a headache to resolder a new one to the battery holder.

With the shape of a box it is very easy to align this robot to different wall and to add very stable pinless attachments to it. The goal of the video is to discuss this feature of this particular robot construction.

Make sure the components are well held in place before soldering. Some soldering station offers clippers that can hold the DIP switch and the PCB; however, you can use a ductype to achieve the same.

While using cardboard to protect the table from solder may look dangerous, solder cools very fast, and the temperature of the soldering gun is much too low to quickly start a fire. It would take deliberate actions to actually cause safety issues with it.

The EV3 Gyro sensor is quite powerful, but there are some little tricks when using it. In the previous episode we showed a hardware solution to the problem and now we are exploring how could the sensor be calibrated from the EV3-G software. Thanks to Sharon and Faye (full names omitted) for the request for this video.

If you screw the bolts too far into the motor, it may stop working. This won’t be an issue later, but if it causes problems now, place a few nuts on the bolt before using it. This will stop the bolt from going too deep into the motor.

The second construction of the series along with a comparison with the first construction. The new robot requires more parts, but has a few more advantages.

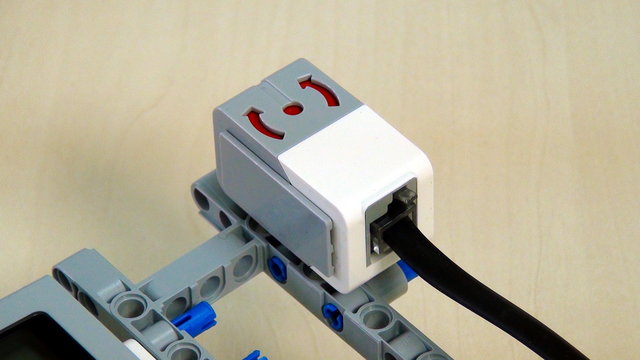

There is a way of mounting the drill bits faster and more reliably than what is shown in this video; however, it requires a steady hand and starting the drill while the drill bit is not yet mounted. We decided that it may pose danger for people not yet savvy with the drill, and that it is best to show how it was intended to be mounted. We strongly advise not using faster methods before you are very comfortable handling this tool.

Много отбори имат проблеми с жироскопичния сензора на EV3 и неговите смущения. В това видео показваме един начин за коригиране на поведението и получаването на точно измерване от този сензор.

The dip switch is mounted by using the holes that are already placed on the PCB board. Meaning that we don't need to drill any holes for it.

Five different robot chassis. This is the goal of the series. To present ideas for different design of the robots and especially the robot bases. If the base is stable and balanced, then in could easily be extended. Let's start with the most simple of the five.

time to plan where everything on the PCB will go. You can rearrange the components as you wish, as long as the wire connections are done correctly after that.

We should how to build a frame that could hold the attachments for specific competition missions. This frame is added in a pinless manner. This means very fast and easy without any glitches of the pins.

If you’ve connected everything correctly, you can now turn on the motor and control its speed using the potentiometer.

The potentiometer is the small knob on the motor speed controller that you can rotate.

Time to make the final connection and complete the prototype.

In this tutorial we present a way to align your robot to a black line. Go through common difficulties, that the teams face, when they need to align their robot, and provide a solution for them.